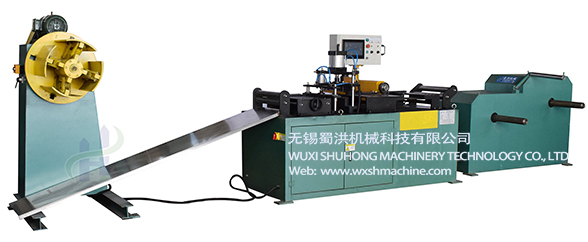

Three - dimensional 3D Transformer Wound Core Cutting Machine

Main features:

1. Apply to silicon steel strip cutting for the three-dimensional triangle wound core

2. Cutting type: curve/ straight

3. Adopt servo motor, PLC control system and touch screen.

4. It has functions like: automatic resetting, automatic adjusting-tool, automatic shutdown, strip parameter setting and real-time display.

5. It is equipped with a variable frequency feeder, material’s position photoelectric detection, no need of storage pit, synchronous operation of feeding speed and cutting speed.

6. It is equipped with a torque receiver. It makes the constant tension of torque operate with the cutting machine synchronously. Material receiving neatly and closely.

7. The machine adopts high precision ball screw, and precision guide to ensure smooth operation, low noise, and long lifetime.

8. Hob uses high quality alloy steel, fast and easy to equip the cutter. It is available for different thickness material.

Technical parameters

Code: SHKL-400

Cutting type: straight/curve

Max feeding width: 400MM

Cutting speed: 0-60M/min

Cutting method: cut one into two strip

Material utilization: 99%

Cutting accuracy: ±0.3MM

Cutting burr: ≤0.03MM

Speed adjusting way: stepless speed regulating